How to adapt to these changes while maintaining profitability?

Manufacturing industry practices are evolving rapidly as the world becomes more digital and interconnected. There is constant pressure on Small and Midsize Businesses (SMBs) to adapt to these changes while maintaining efficiency, quality, and profitability.

This blog post serves as a guide, exploring and explaining the significance of these emerging manufacturing industry trends, their impact, and the advantages they offer for SMBs.

It will discuss how these manufacturing trends can help SMBs enhance their operational efficiency, improve their products’ quality, increase their market share, and drive their growth in the competitive manufacturing industry. For ERP trends, click here.

Trend #1: Smart Factory Evolution - Embracing the Internet of Things (IoT) and Artificial Intelligence (AI)

The Internet of Things (IoT) has been a transformative force across various industries, and manufacturing organizations are no exception. By connecting devices and machines through the internet, IoT enables real-time data sharing, which can significantly maximize efficiency, product quality, and overall business performance. At the beginning of 2020, it was estimated that only 10% of manufacturing businesses had implemented IoT. However, this is expected to increase significantly to 50% by 2025. It is worth noting that some areas of the market are already valued at over $200 billion.

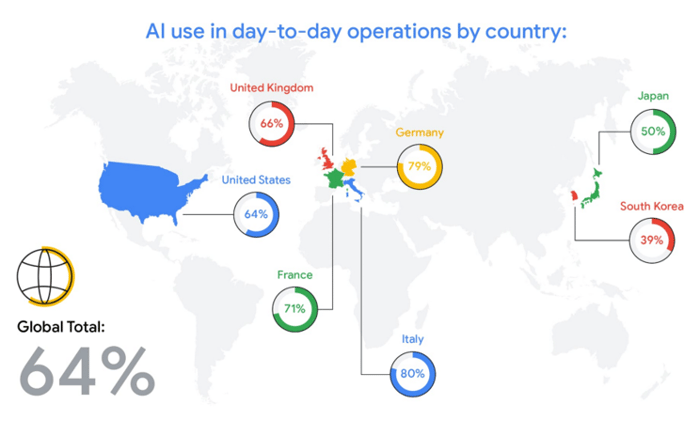

Artificial Intelligence (AI) is emerging as one of the key technologies driving this digital transformation. With its capabilities to learn, reason, and self-correct, AI presents many opportunities for SMBs in the manufacturing sector.

Smart factories, an offshoot of the IoT revolution, refer to an interconnected production environment where machines and systems can communicate and cooperate with each other and humans in real time. It’s an integral part of the Fourth Industrial Revolution, or Industry 4.0 movement, and holds great potential for SMBs in the manufacturing sector.

Implementing IoT in manufacturing, or the Industrial Internet of Things (IIoT), involves the use of sensors and actuators embedded in equipment. These devices collect and transmit data on various operational parameters such as temperature, pressure, humidity, vibration, and energy consumption. The data can then be analyzed to glean valuable insights into the production process.

Some of the benefits of creating smart factories are:

1. Predictive maintenance

By continuously monitoring equipment performance, manufacturing companies can identify potential failure signs and perform maintenance activities before a breakdown occurs. This approach significantly reduces machine downtime, enhances operational efficiency, and prolongs the lifespan of equipment.

Data indicate that predictive maintenance can reduce downtime by 30% to 50%, increase machine life by 20% to 40%, and cut costs by more than 30%. AI algorithms can analyze data from equipment sensors to detect anomalies, predict potential failures, and suggest preventive measures. By accurately predicting machine downtime, manufacturers can plan maintenance activities that minimize disruption to the production process, saving on costs and enhancing productivity.

2. Improves product quality

Manufacturers can quickly detect anomalies and adjust process parameters to prevent defects by monitoring the production process in real time. This not only ensures consistent product quality but also minimizes waste and rework.

Traditional inspection methods are labor-intensive and may only sometimes be effective in detecting defects. AI-powered visual inspection systems, on the other hand, can examine products at high speed with superior precision, identifying defects that the human eye may miss. This not only ensures high product quality but also reduces waste from faulty products.

3. Enhance inventory management

IoT devices can track raw materials and finished products in real time, providing accurate and up-to-date inventory data. This leads to improved demand forecasting, reduced stockouts and overstocking, and optimized inventory costs.

4. Supply chain management

AI-powered forecasting models can analyze complex data sets to predict demand more accurately, helping many manufacturers to plan production and manage inventory more effectively. AI can also monitor real-time data from various points in the supply chain to identify potential disruptions and propose alternate routes or strategies.

While implementing IIoT, artificial intelligence, and smart factories can provide substantial benefits, it also presents challenges. These include the costs associated with acquiring AI technology, a lack of AI expertise, and concerns over data security. However, these challenges are manageable. With a strategic approach to AI adoption, focusing on areas that offer the greatest return on investment and leveraging partnerships with AI vendors or consultants, SMBs can harness the potential of AI to drive their business growth.

Trend #2: Sustainability and Green Manufacturing - The New Norm

The world is increasingly conscious of its ecological footprint, and businesses are no exception. Manufacturing companies, large and small, are starting to realize that sustainability is no longer a mere buzzword but a business imperative. Over 20% of the largest public companies in the world have made promises to achieve net-zero carbon emissions in the future, as the world turns towards sustainability.

For SMBs in the manufacturing sector, embracing green manufacturing practices isn’t just about meeting regulatory requirements or corporate social responsibility—it’s a strategic move that can offer significant competitive advantages. Green manufacturing, or sustainable manufacturing, refers to applying sustainable principles to the production process. This involves reducing waste, minimizing energy use, and limiting the environmental impact while maintaining economic efficiency.

Transitioning to green manufacturing begins with conducting a thorough environmental assessment of the entire manufacturing process. Identifying areas of high energy consumption, waste production, and pollutant emissions can help pinpoint where improvements are necessary.

Lean manufacturing

Lean manufacturing aims to minimize waste without sacrificing productivity. Lean practices, such as just-in-time production, can greatly reduce waste from overproduction and inventory, while practices like 5S can help maintain a clean, efficient, and safe workspace.

Energy efficiency

This can be achieved by optimizing machine operations, upgrading to energy-efficient equipment, and harnessing renewable energy sources. Energy management systems can also be instrumental in monitoring and controlling energy use.

Waste management

This includes minimizing waste production and finding ways to reuse or recycle waste. For instance, some manufacturing companies are turning their waste into valuable byproducts, creating additional revenue streams while reducing their environmental impact. While implementing green manufacturing practices may require an initial investment, the long-term benefits can be substantial. Reduced waste and energy use can lead to significant cost savings, while improved environmental performance can enhance a company’s reputation, increasing customer loyalty and potentially opening up new market opportunities.

Trend #3: The Power of Analytics in Manufacturing

Data Analytics

Data is often referred to as the “new oil”, a valuable resource that, when harnessed correctly, can yield a wealth of insights. For SMBs in the manufacturing sector, data analytics can provide a competitive edge, driving operational efficiency, enhancing product quality, and promoting innovative product development. Data analytics in manufacturing involves collecting, processing, and analyzing large volumes of data from various sources to identify patterns, trends, and correlations. These insights can aid decision-making and strategy formulation, ultimately improving business performance.

Predictive Maintenance

One crucial application of data analytics is predictive maintenance. Traditionally, equipment maintenance was either reactive, dealing with failures as they occurred, or preventative, following a scheduled maintenance program. Both methods have their drawbacks. Reactive maintenance can lead to costly downtime, while preventative maintenance can result in unnecessary servicing of equipment still in good condition. On the other hand, predictive maintenance utilizes data from sensors installed on machinery to monitor their conditions in real time. Advanced analytics can then predict potential failures before they occur, allowing for timely intervention. This approach reduces unplanned downtime, extends machinery life, and saves on maintenance costs.

Product Optimization

Another significant application is in production optimization. Analytics can help identify bottlenecks in the production environments, inefficiencies in resource utilization, and areas of waste. With these insights, manufacturing companies can streamline their manufacturing operations, enhancing productivity and reducing costs.

Product Quality Improvement

Data analytics can also improve product quality by identifying factors contributing to defects or variations in product quality. This allows for adjustments in the production process to mitigate these issues, leading to a higher-quality end product.

Demand Forecasting

Moreover, analytics can help demand forecasting, enabling manufacturers to predict future sales based on historical data and market trends. Accurate demand forecasts lead to better inventory management, reducing stockouts and overstocking and thus optimizing inventory costs.

Incorporating data analytics into complex manufacturing processes is a daunting task for SMBs. It requires investment in data collection and analysis tools like you can find in a manufacturing ERP and hiring or training staff with the necessary skills. However, the potential benefits make it a worthwhile investment. By leveraging the power of analytics, SMBs can transform their operations, gaining a competitive edge in the market.

Trend #4: The Rise of Additive Manufacturing - 3D Printing in Focus

In the last decade, additive manufacturing, commonly known as 3D printing, has moved from the fringes to the forefront of the global manufacturing industry. Offering a highly flexible and cost-effective means of production, 3D printing is transforming the manufacturing landscape, opening up new opportunities for SMBs.

3D printing is an additive manufacturing process that creates objects by depositing layers of material following a digital model. Unlike traditional manufacturing methods, which often involve cutting or drilling from larger pieces of material, 3D printing builds products from the ground up, reducing waste and offering unparalleled design flexibility.

Some of the key advantages of 3D printing for SMBs are:

1. Potential for cost reduction

Traditional manufacturing methods often involve high upfront costs for tooling and setup, making small production runs expensive. 3D printing, on the other hand, requires no tooling, making it a cost-effective option for producing small quantities of products. This feature is particularly beneficial for SMBs, who often produce in smaller volumes compared to large corporations.

2. Rapid prototyping

Manufacturers can create a prototype within hours, accelerating the product development process and reducing time-to-market. Rapid prototyping also facilitates iterative design, allowing manufacturers to quickly test and refine their designs based on feedback.

3D printing opens up possibilities for customization that were previously unimaginable. Manufacturing companies can easily modify digital designs to meet specific customer requirements, allowing mass customization without significantly increasing production costs. This capability can be a significant competitive advantage for SMBs, helping them differentiate themselves in the market.

The technology may not suit all products, particularly those requiring high-strength materials or complex, multi-material designs. Furthermore, the initial cost of 3D printers and materials can be high, and there can be a steep learning curve for those unfamiliar with the technology. However, with the continuous advancement of 3D printing technology and the decrease in associated costs, the opportunities for SMBs are expanding. By strategically integrating 3D printing into their operations, SMBs can enhance their competitiveness and position themselves for growth in the digital manufacturing era.

Trend #5: Building the Fortress - Cybersecurity Measures for Modern Manufacturing

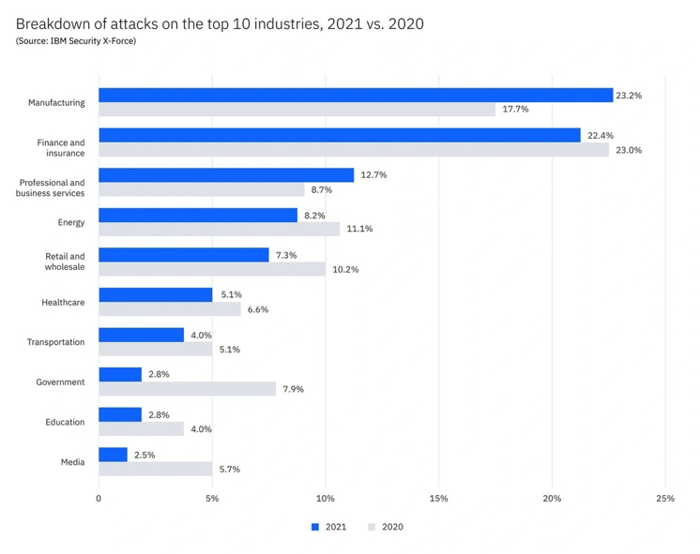

Manufacturing has long been considered a hard hat and high-visibility vest sector. But in the digital age, a new form of protective gear has become essential: cybersecurity. With the increasing interconnection of manufacturing systems and the rise of Industry 4.0, cybersecurity is no longer an IT issue—it’s a manufacturing necessity.

The move towards digitalization in manufacturing companies has brought a host of benefits: increased efficiency, higher quality products, improved flexibility, and more. However, it has also opened the door to cyber threats. These threats range from industrial espionage, where competitors or nation-states seek to steal trade secrets, to cyber vandalism, which can cause significant disruption to production lines.

The consequences of a successful cyberattack can be devastating. It could lead to loss of intellectual property, disruption of production lines, damage to machinery, financial losses, and reputational harm. Given these potential impacts, cybersecurity must be a priority for every SMB involved in manufacturing.

You need to develop a robust cybersecurity strategy to protect your business operations. This involves several phases:

- Risk Assessment: Start by identifying the various cyber risks your business faces. This includes internal risks (e.g., employees unintentionally downloading malicious software) and external risks (e.g., hackers targeting your business).

- Cybersecurity Framework: Develop a framework for managing these risks. This could be based on established standards, such as the NIST Cybersecurity Framework, which provides a structured approach to managing cybersecurity risks.

- Technology Measures: Implement technological solutions to mitigate identified risks. This might include firewalls, intrusion detection systems, and anti-malware software.

- Policies and Procedures: Develop clear policies and procedures to manage cybersecurity risks. This includes procedures for handling suspected cyber incidents and policies on issues such as password management and software updates.

- Training and Awareness: Ensure that all staff are aware of the cyber risks and know how to manage them. This could involve regular training sessions and updates on the latest cyber threats.

- Incident Response Plan: Develop a plan for responding to cyber incidents. This should include steps to isolate affected systems, identify the cause of the incident, and restore normal operations as quickly as possible.

- Regular Reviews: Cyber threats are continually evolving, so reviewing and updating your cybersecurity measures is essential.

In conclusion, cybersecurity is a crucial issue for modern manufacturing SMBs. By understanding the risks, developing a robust cybersecurity strategy, and fostering a culture of cybersecurity awareness, you can significantly reduce your vulnerability to cyber threats.

Trend #6: The New Wage Paradigm - Manufacturers Raising Wages and Reskilling Workers to Combat Labor Shortage

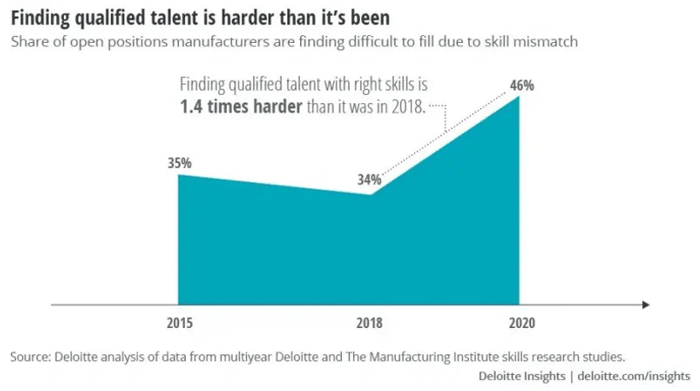

In an era of labor shortages and rapidly evolving skills requirements, attracting and retaining the right talent is a pressing challenge for manufacturers. The solution lies not only in offering competitive wages but also in reskilling existing workers to meet the changing needs of the industry. Manufacturers say finding talent is 36% more difficult than in 2018.

McKinsey predicts the demand for physical and manual skills in repeatable tasks will decline by 30% over the next decade. Labor shortages in the manufacturing industry are driven by various factors, from shifting demographics to the changing perception of manufacturing jobs. The solution to this complex issue is multifaceted and must address both the quantity and quality of labor. Here's 2 workforce development strategies to consider:

Increasing wages can help attract more people to the industry and reduce turnover, while reskilling can ensure workers have the capabilities needed in a digital age. Raising wages is more than just a strategy to attract talent; it’s a reflection of the changing nature of the manufacturing job market. As roles become more complex and technology-driven, they require a higher level of skill and therefore command higher compensation. However, wage increases must be balanced with business sustainability. It’s important to consider the total employee value proposition, which includes salary, benefits, work environment, and opportunities for learning and development.

Reskilling, on the other hand, is a proactive approach to addressing skills gaps in the existing manufacturing workforce. By investing in upskilling and reskilling, manufacturers can ensure their workers are equipped to handle new technologies and processes. A well-executed reskilling program can boost productivity and efficiency and enhance employee engagement and loyalty.

Implementing a reskilling program involves several phases:

- Skills Assessment: Identify the skills your workers currently possess and the ones they will need in the future. This should take into account your strategic plans and technological trends in the industry.

- Learning Pathways: Develop clear pathways for manufacturing employees to acquire the necessary skills. This could involve on-the-job training, mentoring, e-learning, or even partnerships with educational institutions.

- Support and Encouragement: Foster a culture of learning by offering support and encouragement. Recognize and reward progress and make it clear that learning is valued and expected.

- Continual Evaluation: Regularly review and update your reskilling program to ensure it remains relevant as technology and industry needs to evolve.

The dual strategy of raising wages and reskilling workers offers a powerful solution to the labor shortage challenge in the manufacturing industry. By implementing this strategy effectively, SMBs can not only build a capable and committed workforce but also position themselves for success in the digital age.

Conclusion

These leading manufacturing trends show that the modern manufacturing sector is undergoing rapid change, and SMBs are having to adapt quickly in order to remain competitive.

By taking advantage of digital technologies such as 3D printing and cybersecurity measures, SMBs can enhance their efficiency and flexibility while also protecting their operations from cyber threats. With the right strategies in place, SMBs can thrive in this ever-changing sector.

For more insights on how to face the most pressing challenges in process manufacturing , download our ebook.